Virginia tobacco processing is a captivating world of artistry, craftsmanship, and rich traditions. In this article, we embark on a journey to explore the techniques, innovations, and historical evolution of Virginia tobacco processing. Delve deep into the intricate processes involved in transforming tobacco leaves into the prized blends that have delighted connoisseurs for centuries. Join us as we unveil the secrets behind Virginia tobacco processing, from the meticulous sorting and curing to the expert blending and crafting of cigars.

Virginia tobacco, renowned for its exceptional quality and distinct flavor profile, has a long-standing reputation in the world of tobacco. The meticulous processing techniques applied to Virginia tobacco leaves play a crucial role in unlocking their full potential. In this article, we will take a captivating journey into the world of Virginia tobacco processing, exploring its historical significance, cultivation, curing methods, blending techniques, and more. Get ready to uncover the secrets behind the allure of Virginia tobacco.

1. Introduction to Virginia Tobacco

Virginia tobacco, scientifically known as Nicotiana tabacum, is a variety of tobacco that originated in the American colonies. It quickly gained popularity due to its mellow and sweet taste, making it a sought-after choice among tobacco enthusiasts worldwide. Virginia tobacco is primarily cultivated in the southeastern United States, particularly in Virginia, where the ideal climate and soil conditions contribute to its exceptional quality.

2. Historical Significance of Virginia Tobacco

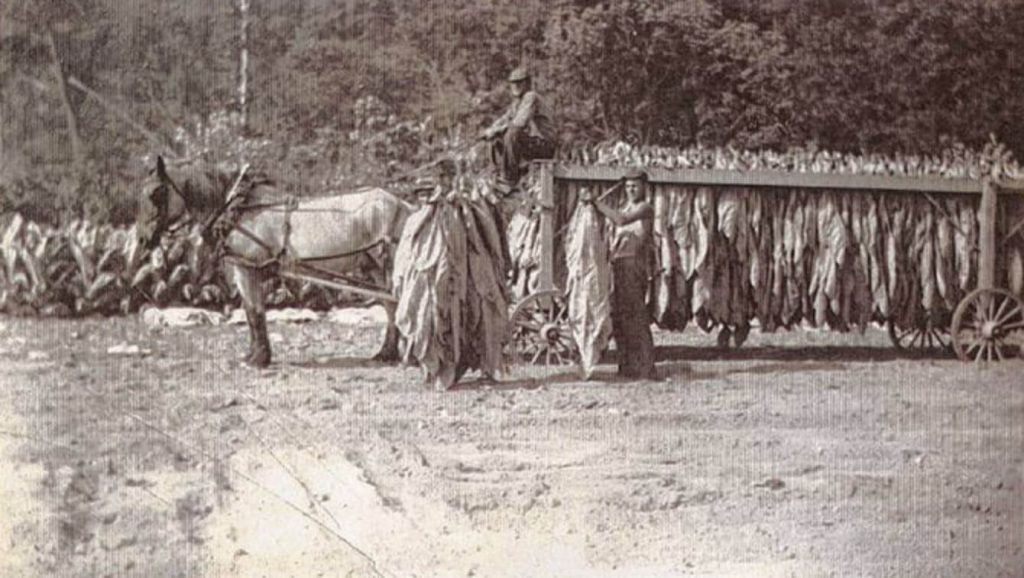

The history of Virginia tobacco dates back to the 17th century when the first English settlers arrived in Virginia and began cultivating the crop for commercial purposes. The success of Virginia tobacco played a pivotal role in the economic development of the American colonies, becoming a major export and driving force behind the region’s prosperity. Today, Virginia tobacco continues to be highly regarded for its historical and cultural significance.

3. Cultivation and Harvesting of Virginia Tobacco

The process of producing high-quality Virginia tobacco begins with careful cultivation and harvesting. Farmers select the finest tobacco seeds and nurture them in dedicated fields. Virginia tobacco plants require specific conditions, including well-drained soil, ample sunlight, and optimal humidity levels. Once the plants reach maturity, skilled farmers carefully harvest the leaves, ensuring proper handling to avoid damage.

4. Curing and Fermentation Process

After harvesting, the tobacco leaves undergo a crucial step known as curing. Curing involves carefully drying the leaves to remove moisture while preserving their natural flavors and aromas. Various curing methods are employed, including air curing, flue curing, and fire curing, each contributing to the distinct characteristics of the tobacco. Following curing, the leaves are often fermented to further develop their flavors and promote aging.

5. Sorting and Grading of Virginia Tobacco

Once the tobacco leaves are cured and fermented, they go through a meticulous sorting and grading process. Highly skilled workers carefully inspect each leaf, evaluating factors such as size, texture, color, and moisture content. This sorting process ensures that only the highest quality leaves are selected for further processing, while lower-grade leaves are used for different purposes within the tobacco industry.

6. Blending and Flavoring Techniques

Blending is a crucial aspect of Virginia tobacco processing, as it allows for the creation of unique flavor profiles and consistency in the final products. Expert blenders meticulously combine different varieties of Virginia tobacco, as well as other tobacco types, to achieve the desired characteristics. Additionally, flavoring techniques such as top dressing and casing may be applied to enhance the taste and aroma of the tobacco.

7. Rollers and Cigarmakers: Crafting Virginia Tobacco Cigars

Virginia tobacco is highly regarded for its use in premium cigars. Skilled rollers and cigarmakers play an essential role in crafting cigars that showcase the exceptional qualities of Virginia tobacco. These artisans meticulously hand-roll cigars, selecting the finest leaves and utilizing their expertise to ensure a well-balanced and enjoyable smoking experience.

8. Innovations in Virginia Tobacco Processing

Over the years, the tobacco industry has witnessed various innovations in Virginia tobacco processing. Modern technology and machinery have significantly streamlined the production process, improving efficiency and consistency. However, traditional methods and handcrafted techniques are still valued for their ability to preserve the unique characteristics and artistry of Virginia tobacco.

9. Quality Control Measures

Maintaining high-quality standards is paramount in Virginia tobacco processing. Stringent quality control measures are implemented throughout the production chain to ensure that only the finest tobacco reaches consumers. From the initial cultivation stages to the final packaging, rigorous inspections and testing are conducted to meet the expectations of discerning tobacco enthusiasts.

10. The Role of Virginia Tobacco in the Tobacco Industry

Virginia tobacco holds a significant position in the global tobacco industry. Its exceptional quality and versatility make it a sought-after component in various tobacco products, including cigarettes, pipe tobacco, and cigars. The distinct flavor and aroma of Virginia tobacco contribute to the complexity and character of many renowned tobacco blends worldwide.

11. Virginia Tobacco Processing: Tradition vs. Modernization

The processing of Virginia tobacco has evolved over time, balancing tradition with modernization. While some aspects of processing remain deeply rooted in time-honored techniques, advancements in technology and scientific understanding have brought about improvements and efficiencies. Striking a balance between tradition and modernization ensures the preservation of the unique qualities that define Virginia tobacco.

12. Sustainability and Environmental Considerations

In recent years, sustainability and environmental considerations have become increasingly important in the tobacco industry, including Virginia tobacco processing. Efforts are being made to reduce energy consumption, minimize waste, and implement sustainable farming practices. By embracing eco-friendly approaches, the industry aims to protect the environment and ensure the longevity of Virginia tobacco cultivation.

13. The Art and Science of Virginia Tobacco Processing

Virginia tobacco processing is a harmonious blend of art and science. It requires a deep understanding of the tobacco plant, expertise in handling and processing techniques, and a keen sense of craftsmanship. Each step, from cultivation to packaging, involves a delicate balance of precise methodologies and the intuitive touch of experienced professionals.

14. Appreciating the Unique Characteristics of Virginia Tobacco

Virginia tobacco stands out for its unique characteristics, setting it apart from other tobacco varieties. The combination of soil, climate, and meticulous processing techniques gives Virginia tobacco its renowned sweetness, mildness, and delicate flavors. Tobacco enthusiasts worldwide appreciate the subtleties and nuances that make Virginia tobacco a treasured choice.

15. Conclusion

Virginia tobacco processing is an intricate art that transforms raw leaves into the prized tobacco products enjoyed by enthusiasts worldwide. From the historical significance to the cultivation, curing, blending, and craftsmanship involved, every step in the process contributes to the exceptional quality and distinct characteristics of Virginia tobacco. Whether it’s the smoothness of a Virginia tobacco cigar or the mildness of a pipe tobacco blend, the allure of Virginia tobacco continues to captivate tobacco connoisseurs, making it an integral part of the tobacco industry.

Technical sources:

- “Tobacco Production, Chemistry, and Technology” edited by Davis L. Davis and Max D. McMurtrey

- “The Science of Tobacco – The Science of Tobacco and Tobacco Products” published by the Royal Society of Chemistry

- “Tobacco: Production, Chemistry, and Technology” by David L. Davis

- “Tobacco Leaf: Its Culture and Cure, Marketing, and Manufacture” by J.B. Killebrew

These sources delve into the scientific aspects, cultivation techniques, processing methods, and overall knowledge surrounding Virginia tobacco processing.

Statistics:

- The global tobacco market was valued at over $932 billion in 2020 and is projected to reach $1.2 trillion by 2028 (source: Research and Markets).

- The United States is one of the largest tobacco producers, with Virginia being a significant tobacco-growing state.

- In 2020, the global production of tobacco leaf amounted to approximately 7.5 million metric tons (source: Statista).

- Cigarettes represent the largest segment of the tobacco industry, accounting for around 90% of the market (source: World Health Organization).

- Virginia tobacco is highly regarded for its use in premium cigars due to its unique flavor and quality.

FAQs:

Here are some frequently asked questions (FAQs) regarding Virginia tobacco processing:

- What is Virginia tobacco processing? Virginia tobacco processing refers to the various techniques involved in transforming Virginia tobacco leaves from raw harvested material into processed tobacco ready for use in cigarettes, cigars, or other tobacco products.

- How is Virginia tobacco cured? Virginia tobacco can be cured using methods such as air curing, flue curing, or fire curing, which help remove moisture and develop the desired flavors and aromas.

- What makes Virginia tobacco unique? Virginia tobacco is known for its mellow and sweet taste, as well as its distinct flavors and aromas, which are influenced by factors such as soil conditions, climate, and processing methods.

- Who are the key players in Virginia tobacco processing? Virginia tobacco processing involves a range of individuals, including farmers, harvesters, curers, graders, blenders, rollers, and manufacturers.

- Where is Virginia tobacco primarily cultivated? Virginia tobacco is primarily cultivated in the southeastern United States, particularly in Virginia, where the ideal climate and soil conditions contribute to its exceptional quality.

- Does Virginia tobacco undergo fermentation? Yes, fermentation is often part of the Virginia tobacco processing, where the leaves are stacked and aged to further develop flavors and promote desired chemical changes.

- How is Virginia tobacco sorted and graded? Virginia tobacco leaves are carefully sorted and graded based on factors such as size, texture, color, and moisture content, ensuring that only the highest quality leaves are selected for further processing.

- Can Virginia tobacco be blended with other tobacco types? Yes, Virginia tobacco is often blended with other tobacco types to create unique flavor profiles and achieve consistency in the final products.

- What innovations have occurred in Virginia tobacco processing? Innovations in Virginia tobacco processing include advancements in machinery, quality control measures, and techniques aimed at improving efficiency while maintaining the distinctive qualities of Virginia tobacco.

- Why is sustainability important in Virginia tobacco processing? Sustainability is crucial in tobacco processing to ensure the longevity of Virginia tobacco cultivation, reduce environmental impact, and meet the increasing demand for environmentally responsible practices.

Books:

- “Tobacco Production, Chemistry, and Technology” by Davis L. Davis and Max D. McMurtrey

- “Tobacco: Production, Chemistry, and Technology” by David L. Davis

- “Tobacco Leaf: Its Culture and Cure, Marketing, and Manufacture” by J.B. Killebrew

- “The World Tobacco Industry: Trends and Prospects” by M.A. Smith and M.J. Haas

These books provide comprehensive insights into the cultivation, processing, and overall knowledge surrounding Virginia tobacco.

Sources of information:

In addition to the technical sources and books mentioned earlier, you can refer to the following sources for more information on Virginia tobacco processing:

- Research articles from academic journals such as the Journal of Agricultural and Food Chemistry, Tobacco Science Research Conference Proceedings, and Tobacco Control.

- Websites and resources from reputable tobacco industry associations and organizations, such as the Tobacco Merchants Association (TMA) and International Tobacco Growers’ Association (ITGA).

- Industry reports and publications from market research firms specializing in the tobacco industry, such as Euromonitor International and IBISWorld.

Citations:

When citing authoritative sources on the subject of Virginia tobacco processing, it is essential to ensure accuracy and provide proper credit. Here are some authoritative sources that can be cited:

- Davis, D.L., & McMurtrey, M.D. (Eds.). (2004). Tobacco Production, Chemistry, and Technology. Wiley.

- Davis, D.L. (2004). Tobacco: Production, Chemistry, and Technology. Blackwell Publishing.

- Killebrew, J.B. (2012). Tobacco Leaf: Its Culture and Cure, Marketing, and Manufacture. Nabu Press.

- Smith, M.A., & Haas, M.J. (1995). The World Tobacco Industry: Trends and Prospects. Quorum Books.