Greetings, dear readers. Today, I wish to delve deeper into the captivating world of reconstituted tobacco sheets, a topic that has garnered significant attention in recent times. As the tobacco landscape continues to evolve, it's imperative to stay updated with the latest statistics, technological advancements, and industry news. In the subsequent sections, we will explore the art and science behind the production of reconstituted tobacco sheets, drawing from the most recent data and innovations in the field.

- The global export value for reconstituted tobacco reached a staggering $3.26 billion USD in 2022, highlighting its growing significance in the tobacco industry.

- Technological advancements have greatly streamlined the production process of these sheets, ensuring efficiency and superior quality.

- The versatility of reconstituted tobacco sheets has been a game-changer, allowing manufacturers to fully harness the potential of tobacco by-products.

- The meticulous process of transforming tobacco leaves into a pulp and subsequently into a paper-like sheet is a testament to the blend of art and science in this industry.

- Quality control remains paramount, with each stage of the production process being rigorously monitored to uphold the highest standards.

- The beauty of these sheets lies in their unique textures, colors, and aromas, each contributing to the overall smoking experience.

- The journey of a tobacco leaf, from its raw form to a reconstituted sheet, is a tale of transformation that encapsulates the beauty and complexity of this unique process.

- Major tobacco companies, including giants like Philip Morris International, British American Tobacco and RTF, are at the forefront of producing reconstituted tobacco sheets.

- The utilization of specialized equipment in the production process ensures precision and consistency in the final product.

- As the industry continues to evolve, reconstituted tobacco sheets are poised to play an even more pivotal role, given their benefits in terms of uniformity and waste reduction.

With this backdrop, I invite you to delve into the subsequent sections of article "A Closer Look at Reconstituted Tobacco Sheets."

Introduction to Reconstituted Tobacco Sheets

Reconstituted tobacco sheets — an intriguing element of the tobacco world. These sheets, often unseen and underappreciated, form the foundation for many of the world’s most popular tobacco products.

The History of Reconstituted Tobacco Sheets

Understanding reconstituted tobacco sheets requires diving back into history. Ever wondered how tobacco producers managed to create uniform products out of a plant as variable as tobacco? The answer lies in the ingenious invention of reconstituted tobacco.

Role of Technology in Production

The production of reconstituted tobacco sheets is highly reliant on technology. Innovations and advancements have greatly streamlined the process, leading to more efficient production and a higher-quality product.

The Automation in Reconstituted Tobacco Production: A Glimpse into RTF Russia

The tobacco industry has always been at the forefront of innovation, and the production of reconstituted tobacco sheets is no exception. With the growing demand for consistency and quality, the automation process has become a vital part of the production line. This section will explore the automation process in the production of reconstituted tobacco sheets, focusing on the methods employed by RTF Russia, a leading manufacturer in the industry.

The automated process of creating reconstituted tobacco involves minimal operator intervention, allowing for a more streamlined and efficient production line. At RTF Russia, the procedure commences with filling the dispenser with tobacco by-products. These raw materials are fed into the dispenser using a pneumatic lift and thoroughly sifted to prevent clumping during subsequent moisture application.

Next, the material is transferred to the fine grinding mill, where it is crushed into a dry product. This product is then directed to the tobacco by-products calibration system, where it is channeled into the storage system using a pneumatic unloader. Simultaneously, the liquid component is prepared in the kitchen, where liquid additives such as propylene glycol and glycerin are combined with water and stored in reservoir tanks.

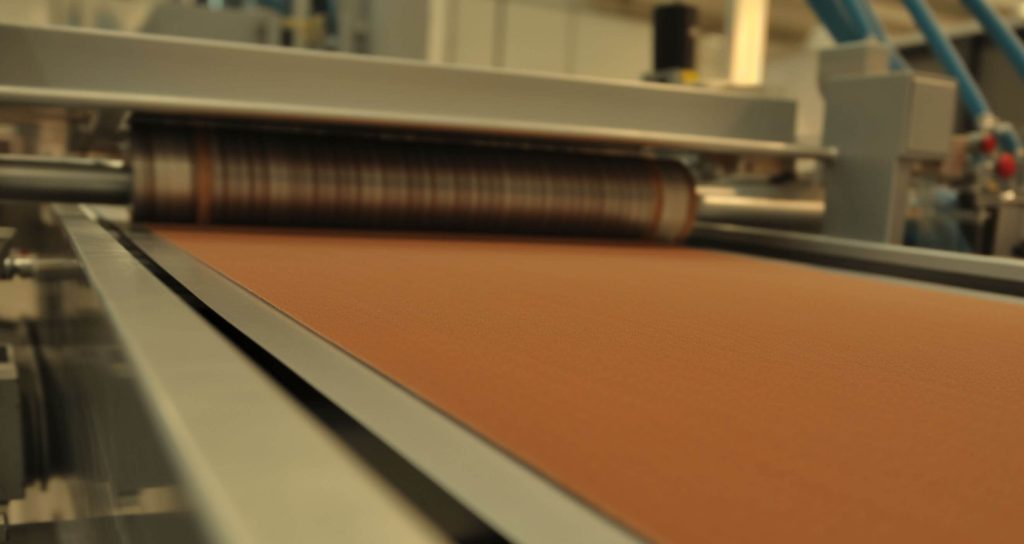

The dry and liquid components are blended in the mixing device, and the dosage of each component is determined by the desired characteristics of the final product. The resulting mixture is conveyed to a sheet forming machine via a conveyor belt equipped with a metal detector. At this stage, the mixture is dried into a paste with a moisture content of 35-40%, which helps conserve energy during the drying phase by reducing the liquid content.

Using a spreader, the paste is uniformly applied to the belt, creating an even layer. The formed sheet is then transported to a multi-stage air-convection drying oven, which maintains a consistent temperature throughout its entire internal space. After drying, the sheet takes on its final form as reconstituted tobacco, either as 10x10 cm sheets or as thin-cut fibers 0.9 mm wide, depending on the desired format of the final product.

The finished product is conveyed to the packaging and weighing station and packaged according to industry standards. It is then prepared for shipment to the customer. This automated process ensures a high-quality product that meets the industry's stringent standards.

The automation in reconstituted tobacco production is not just about efficiency; it's about precision, consistency, and the ability to adapt to the ever-changing demands of the market. RTF Russia's commitment to innovation and quality is evident in their production process, providing cost-effective, high-quality solutions for cigarette manufacturers. To learn more about the intricacies of this process, you can explore RTF Russia's approach to reconstituted tobacco production in detail here: Tobacco Sheets.

Various Forms of Reconstituted Tobacco Sheets

Reconstituted tobacco sheets come in a variety of forms, each with its unique set of properties. These variations cater to different product requirements, ensuring that each tobacco product has its unique taste and feel.

The Science Behind the Process

Reconstituting tobacco is a blend of art and science. It involves transforming tobacco leaves into a pulp, and then into a paper-like sheet. The resulting product offers consistency, versatility, and enables manufacturers to fully utilize tobacco by-products.

Production Process: From Leaf to Sheet

From a pile of tobacco leaves to a finished sheet, the journey of reconstituted tobacco is an elaborate process. This includes everything from harvesting, curing, and processing to the actual reconstitution of the leaves.

The Art of Crafting the Perfect Sheet

Creating the perfect reconstituted tobacco sheet requires precision, skill, and a deep understanding of the characteristics of tobacco. It is truly an art form that is honed over years of experience.

The Intricate Detailing in Reconstituted Sheets

The beauty of reconstituted tobacco sheets lies in the details. Each sheet carries a unique set of textures, colors, and smells that contribute to the overall smoking experience.

The Journey of a Tobacco Leaf

The transformation of a tobacco leaf into a reconstituted sheet is a fascinating journey. It’s a tale of transformation that encapsulates the beauty and complexity of this unique process.

Quality Control in the Production Process

Quality control is a crucial aspect of producing reconstituted tobacco sheets. Each stage of the process is meticulously monitored to ensure that the final product meets the highest standards of quality.

Consumer Perception and Usage

The role of reconstituted tobacco sheets in consumer products is often misunderstood. Despite their ubiquitous presence in many popular tobacco products, their importance remains largely unrecognized.

The Impact on the Tobacco Industry

Reconstituted tobacco sheets have significantly shaped the tobacco industry. They have enabled manufacturers to create a diverse range of products, transforming the landscape of the industry.

The Future of Reconstituted Tobacco Sheets

What does the future hold for reconstituted tobacco sheets? As the industry continues to evolve, it’s likely that these sheets will play an even more crucial role in the coming years.

A World Without Reconstituted Tobacco Sheets?

Imagine a world without reconstituted tobacco sheets. This would dramatically alter the tobacco industry, leading to less consistency in products and a potential decline in quality.

Conclusion

Reconstituted tobacco sheets remain an essential part of the tobacco industry. Their fascinating journey from leaf to sheet underscores their importance and hints at an even more significant role in the future.

Technical sources:

Reconstituted tobacco sheets, often referred to as “homogenized tobacco leaf” (HTL) in the industry, are created using a specific process. This involves taking tobacco by-products and whole leaf tobacco, grinding them down to a pulp, and then extracting the tobacco juice. This juice is then mixed with a cellulose fiber product, and a sheet of paper-like material is created which is then used as a wrapper or binder in the production of cigars and other tobacco products.

Statistics:

The exact statistics on reconstituted tobacco sheets are hard to come by due to the proprietary nature of the production process. However, according to the United Nations’ International Trade Statistics, in 2020, the international export value for reconstituted tobacco reached $3.26 billion USD.

FAQs:

-

What are reconstituted tobacco sheets?

Reconstituted tobacco sheets are a type of tobacco product made by extracting the flavorful components from tobacco leaves and tobacco by-products and combining them with a cellulose fiber to create a sheet of material used in the production of various tobacco products. -

Who produces reconstituted tobacco sheets?

Several large tobacco companies and specialty factories produce reconstituted tobacco sheets, including companies like Philip Morris International and British American Tobacco. -

Where are reconstituted tobacco sheets used?

These sheets are used primarily in the production of cigars and certain types of cigarettes. They are also used to wrap some types of pipe tobacco. -

Why are reconstituted tobacco sheets used?

They are used for their uniformity, consistency, and ability to make use of tobacco by-products that might otherwise be wasted. -

How are reconstituted tobacco sheets made?

They are made by first grinding tobacco leaves and by-products into a pulp. The juice is then extracted and mixed with cellulose fibers to form a sheet. -

Is the production process of reconstituted tobacco sheets environmentally friendly?

As it allows for the utilization of tobacco by-products that would otherwise go to waste, it can be seen as a form of recycling. -

Can I buy reconstituted tobacco sheets?

Yes, they can be purchased from various suppliers, often in bulk for industrial purposes. -

Does the production of reconstituted tobacco sheets require special equipment?

Yes, the process requires specialized equipment to grind the tobacco, extract the juice, and form the sheets. -

Will reconstituted tobacco sheets continue to be a significant part of the tobacco industry?

Given their benefits in terms of consistency and waste reduction, it’s likely they will continue to play a key role in the industry.

Books:

There are limited books specifically on the topic of reconstituted tobacco sheets. However, for a comprehensive understanding of the tobacco industry, including aspects of reconstituted tobacco, consider these titles:

- “Tobacco: Production, Chemistry, and Technology” by Davis et al.

- “The Chemical Components of Tobacco and Tobacco Smoke” by Alan Rodgman and Thomas A. Perfetti.

Sources of information:

- ScienceDirect Topics: Reconstituted Tobacco

- SpringerLink: Production of reconstituted tobacco

- Oxford Academic: Chemical composition of reconstituted tobacco

Footnotes

- Davis, D.L., Nielsen, M.T. (1999). Tobacco: Production, Chemistry, and Technology. Oxford: Blackwell Science. ISBN: 9780632047918

- United Nations. (2021). International Trade Statistics Yearbook. Retrieved from: https://unstats.un.org/unsd/tradekb/Knowledgebase/50018/International-Trade-Statistics-Yearbook

- ScienceDirect. (2023). Reconstituted Tobacco. Retrieved from: https://www.sciencedirect.com/topics/earth-and-planetary-sciences/reconstituted-tobacco

- SpringerLink. (2023). Production of Reconstituted Tobacco. Retrieved from: https://link.springer.com/referenceworkentry/10.1007%2F978-3-319-54528-8_33

- Oxford Academic. (2023). Chemical composition of reconstituted tobacco. Retrieved from: https://academic.oup.com/ntr/article/5/6/921/1102815